PICKLING

The pickling is acid etching with another name, a form of chemical descale.

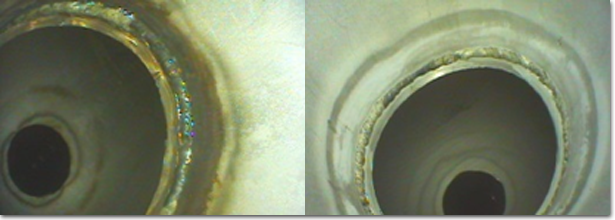

The descale means the removal of the strong bonding oxide layers formed during warm formatting, heat treatment, welding and other operations that require high heat. In most cases the producer delivers the structural pieces, tubes, and tanks already descaled, however, it appears many times that descale is necessary because of welding and other operations that require high heat. The Inhibit Svelto Kft. takes over those on-site pickling procedures where the circulation and evacuation of the pickling acid is possible.

The pickling procedure is hardly tracking action from the analytical standpoint, therefore, our company uses the standard ASTM A380/A380M chemical treatments. (The uniform cleaning procedure of pickling and descaling of stainless metal equipment, appliances, and systems)

We pick out the necessary chemical for the pickling based on the mentioned standard, the quality of the structural equipment and request of the customer. Just like with any other on-site chemical cleaning we work out the price offer during a free field survey. A rough technological description which includes the main effectuation parameters is included in the price offer.

PASSIVATING

The concept of passivation is used regularly on significantly different operations and procedures connected with stainless metal. In order to avoid any misunderstandings of the requirements, it could be useful to name punctually which meaning of the word the customer uses. Here are some of the rife meanings that can be passivation.

Passivation is a procedure when stainless steel meets with air or other environment containing oxygen, and creates a chemically inactive surface spontaneously.

Passivation is the removal of exogen iron or other iron compounds from the stainless metal surface with some kind of chemical melting. Typically, acid used on the surface that has no significant effect on the stainless steel while cleaning the surface from contamination.

Passivation is a chemical treatment when the stainless steel is treated with a weak oxidisable chemical, for example nitric acid in order to help the development of a spontaneous passive protective surface.

The development of a spontaneous passive protective surface is not only aesthetically important, but the restoration of the steel’s protecting qualities inhibit the speeding up of the corrosion processes, and the contamination of the surroundings of the steel. See at rouge removal here.LINK

Our company handles each individual system or equipment as a unique order, even so there are general rules and standard technologies, therefore, a shared inspection where we make the main parameters of the order is useful for both parties. The on-site inspection is free, call our company courageously!

The definitions above apply to stainless steel. This means, to avoid any misunderstandings, we cannot talk about the passivation for low trained steel. In this case the process could rather be forming of a temporary protection, but this seems a bit circumstantial

With further theoretical details we do not want to burden the kind inquirer. According to the solvable situation, our company may suggest the following chemical treatment:

Pickling, passivating and degrouging of stainless steel. Further information on degrouging here.LINK

Just like the passivation, we do the pickling with the standard ASTM A380/A380M.

The pickling and passivating of low compound steel. Here the passivation means forming of a temporary protection. This can happen in a chemical way, forming an iron-phosphate layer, or in a physical way, forming a special corrosion protecting layer on the surface of the steel. The life span of these layers can go from two weeks to two years.