Our company cleans hundreds of heat exchangers yearly at different locations. In most cases the deposit is scale. Separated scale can have many reasons, and their source and quality are not identical either. The common practice is to remove the scale with some kind of mineral or organic acid. The features of the scale (oxide, carbonate, silicat etc.) and the organic material (carbon steel, acid-proof steel, aluminium, copper, zincked etc.) of the apparatus greatly influences the applicable acids’ quality and using parameters.

Why is it necessary to remove the deposited scale?

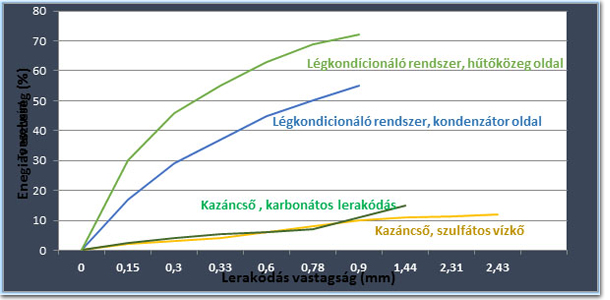

- Loss of energy

- Corrosion

- Risk of explosion

- Not scheduled stoppage

Many years of our company's experience, and the used modern corrosion inhibitors are the guarantee for non damage of the used chemical on the apparatus’s organic material.

ADVANTAGES:

- No need for disassemble ⇒ → Shorter stopping time

- The scale on the surface chemically fade away ⇒ Clean metal surface

- Our chemicals include inhibitors ⇒ No corrosion danger

- Picking our chemicals is fémfelület és based on the metal surface and the deposition ⇒ Efficient and fast cleaning

- Working with own developed chemicals ⇒ Economical

- Tracking of scale deposition with analytical measures ⇒ Optimal cleaning time and economical chemical usage

- The cleaning is closed and effusion free ⇒ Clean workspace, environment-friendly