This service is done on site, in the course of a chemical contamination removal or surface conditioning with a mobile equipment that creates a circulation without the disassembly of the apparatus of the technological cycle. The circulation is flexible; could be used with relatively small tube diameter. During the circulation the size of the equipment to be cleaned does not affect the feasibility, the amount of the circulated chemical can go from 15 liters to 50 m3.

ADVANTAGES:

- No disassemble of the apparatus

- Environment-friendly

- Fast, contamination specific

- Shorter stopping time

- Perfectly clean surface

Nonexhaustive overview of cleaning technologies:

DESCALING

Scale separation can be often found on appliances with thermal equipment like heat exchangers, boilers, condensers etc, especially if the water is not softened properly. The separated and deposited scale have several damaging consequences:

- reducing the heat transfering area, therefore more energy is needed for the same efficiency

- damaging the structural materials, gaskets

- reducing the cross-sections that causes blockages in worst cases, so ends up in malfunction

- the deposited scale excellent substrate for bacteriums, and fungus

PICKLING / PASSIVATING

Our company can do various appliances and technological units maintenance like pickling and passivating before starting them up.

CLEANING OF AIR COOLERS

Our company takes on the duties of outside air coolers and inside heat transfer surfaces chemical cleaning.

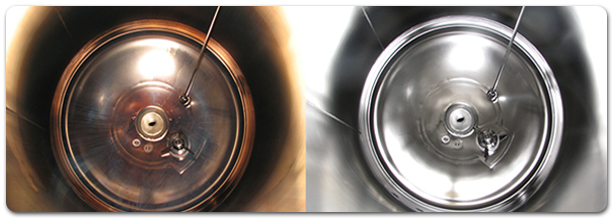

PHARMACEUTICAL INDUSTRY-DEROUGING

Our company takes on the duties of the degrouging of technologies using pharmaceutical industry cleaned water and steam.